Date

June 8, 1998

Document

- View PDF (1 MB)

Description

While the production of nuclear weapons has historically been important in United States foreign relations, there is also a high risk that comes with producing, storing, and maintaining these weapons. In the early days of nuclear weapons, it was standard to keep the nuclear material away from the weapon until absolutely necessary, with assembly often being performed in the cargo bay as the aircraft was flying toward the target. However, as tensions mounted in the Cold War this strategy became impractical as weapons needed to be ready at a moment’s notice in case of a Soviet attack. As the nuclear material could no longer be kept disassembled, more safety features were required to prevent accidental detonation. This need for more resilient safety features was exacerbated by 32 accidents involving nuclear weapons between 1950 and 1980.

Early safety features controlled electrical contacts and isolated critical electrical cables from one another to prevent unwanted sparking and degradation of vital components. However, a lot of assumptions on the likelihood of a detonation in the event of an accident were made about nuclear weapons that had no actual basis in reality. Early nuclear weapons were created without safety devices as engineers assumed the weapon would fail in an accident before it would detonate.

To decrease the likelihood of accidental detonation, the principles of Enhanced Nuclear Detonation Safety (ENDS) were created. These principles reduced the number of components involved in nuclear safety. This concept is characterized by the “3 Is,” isolation, incompatibility, and interoperability. Critical components of the weapons need to be isolated inside of an energy barrier. The action that passes through the barrier to create the nuclear detonation must be incompatible with naturally occuring signals. Finally, in an accident, some of the elements of the weapon must become inoperable quickly enough to prevent detonation.

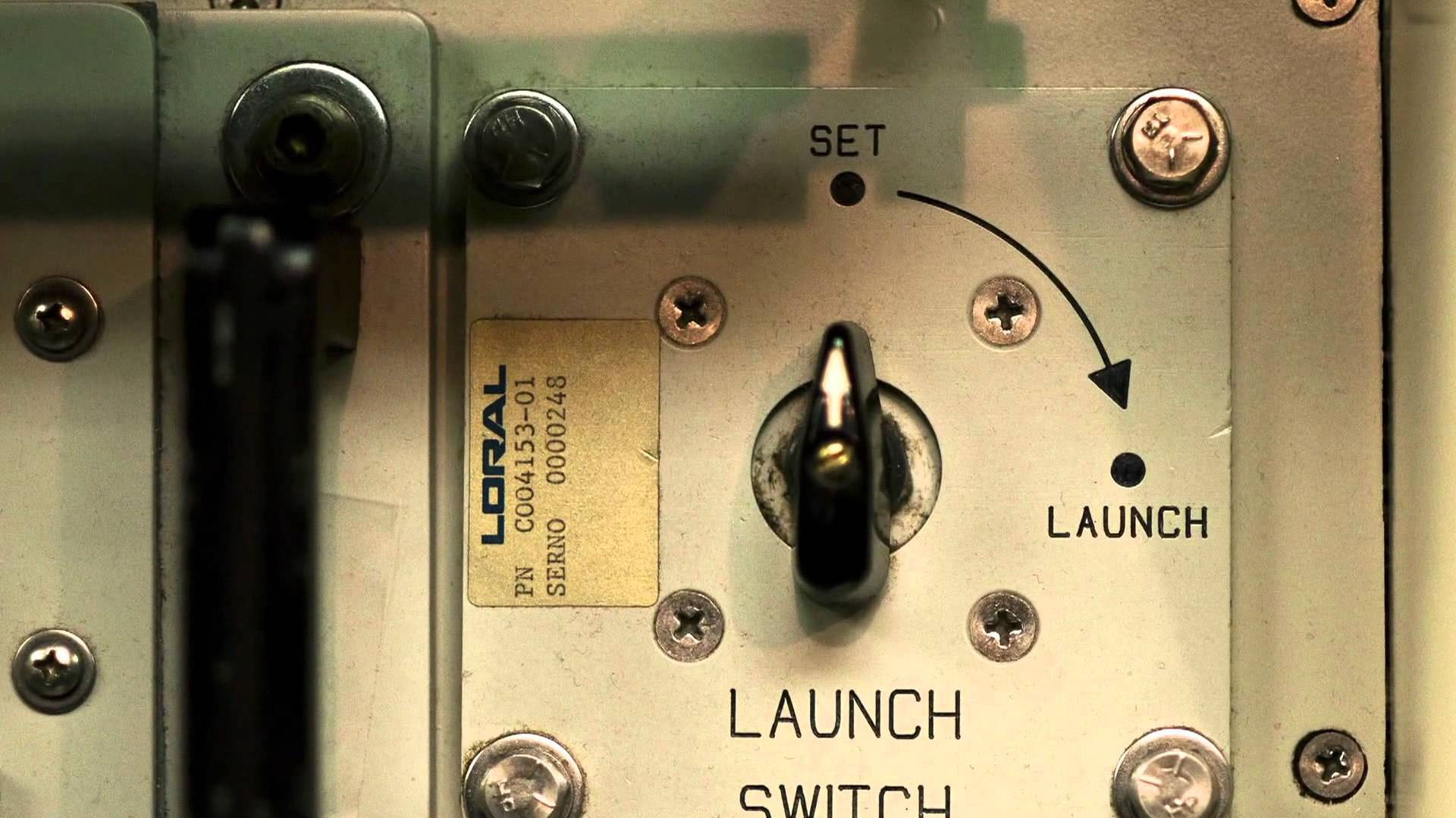

Two other fundamental designs in nuclear safety are “stronglinks” and “weaklinks.” Stronglinks are rugged mechanical devices designed to withstand the rugged environment they are expected to experience. There are four elements in this category: drivers, pattern discriminators, energy control elements, and status monitors (for further details, see article). Weaklinks are elements designed to break down in an accident in order to prevent the weapon from detonating. A common thermal weaklink is a capacitor that would be destroyed in a fire or other unusually hot environments.

The article goes on to discuss how the U.S. ensures safety features are meeting necessary standards through a series of assessments. A review is conducted by an independent safety group with no affiliation to the group that designed and manufactured the safety components. Congress will also issue safety reviews to thoroughly check these weapons.

After the Cold War ended, the production of nuclear weapons stopped. However, the ones that currently exist need to be maintained. Components with short lifespans of nuclear weapons are beginning to degrade, and many early weapons do not have important safety devices such as stronglinks, and nor enough space designed into the firing system to insert stronglinks. The new challenge in nuclear safety is to create new stronglinks that are small enough to be inserted into older nuclear weapons without compromising their effectiveness. Two promising solutions further discussed in the article are multilevel silicon surface micromachining and LIGA (lithography, electroplating, and molding).

Citation

Plummer, David, and William Greenwood. “The history of nuclear weapon safety devices.” In 34th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, p. 3464. 1998.

Provenance

Obtained from columbia.edu

Topics

Document entry started by Jordan Cory on August 26, 2020. Entry last updated by Jordan Cory on August 26, 2020.